With the above info, first-time clients will have the ability to recognize which valve will certainly appropriate for their industrial applications. It is constantly a great idea to consult a shutoff vendor prior to making a decision. Relevant Messages Comprehending Industrial Control Valves and also their Kinds was last customized: July 12th, 2017 by.

Worldwide Pipe distributes a wide range of valve items from various suppliers. What is an Industrial Valve?

Module I concentrates on valves as tools, checking out exactly how they work and the main types commonly made use of in the Oil & Gas market. Module II was created to give a wider view of the different secondary processes that surround a valve application, such vendor auditing and prototype screening.

Some Known Factual Statements About High Pressure Cryogenic Valves

In this short article, I will offer an introduction of one of the most popular shutoff failings as well as exactly how it can be feasible to avoid or lower the regularity of such problems. I'm completely mindful that we have a really vast topic here. There are numerous different shutoff types, applications, as well as processes that there would be sufficient "stuff" to compose a publication about it!" In any kind of case and nonetheless the application, numerous shutoff users experiencing similar troubles.

Speaking about "valve failings" we normally think of; Seat leak, loading leakage or a valve obtaining blocked in open or closed position. Here it is extremely vital to recognize that such failures in lots of instances are just consequences of errors made long prior to the shutoff starts to leakage. In my 25 years of taking a trip the globe and also going to Power Plants and also Refineries, in greater than 80% of the cases, the valves have actually been mistakenly chosen at first of a project.

Right here is my listing of the most prominent factors for valve failings: Use of the elastomers, seats, seals, as well as gaskets Use of the shutoff stem Cavitation Temperatures or stress outside the designed operating criteria, particularly unanticipated stress peaks in the pipeline (typical mistake made is to develop valves to operating conditions and not layout conditions) Incorrectly chosen actuators (for instance to much pressure on the seat while closing) International particles in the pipe (for example inadequate Blow-Out after welding, or missing out on filters) Product conflict with the item being processed ending up in rust Inaccurate assembly, installation, or maintenance procedures performed on shutoff The very first 2 points, even with a valve selected correctly, regrettably, there is the reality that every elastomer, seat, gasket, round, etc

Taking into consideration the problem of the application (for example high temperatures/pressures, abrasive tools, high speeds) the failure of these parts after a particular time of use, can be considered as "typical".

An intriguing point is the problem. I have been entailed over the years in numerous cases of failings of Swing Examine Valves. Sometimes unsubstantiated, however there are people outside setting up a Swing Check Shutoff inverted or in the incorrect instructions! One more very common problem with Swing Examine Shutoffs (as well as likewise other sorts of Inspect Shutoffs) is that during installment it has not been thought about that there must be a particular range from a pipe elbow to the shutoff, or from a pump electrical outlet to the valve.

Get This Report about Hydrogen Valves

Obligation indicates likewise functioning in a preventive method. Understandable, yet technically accurate Setup, Upkeep, and Running handbooks need to be a requirement for everyone. Financial investment in brand-new modern technologies which can minimize failures is possibly the largest obstacle of the shutoff sector over the next years. Lastly.

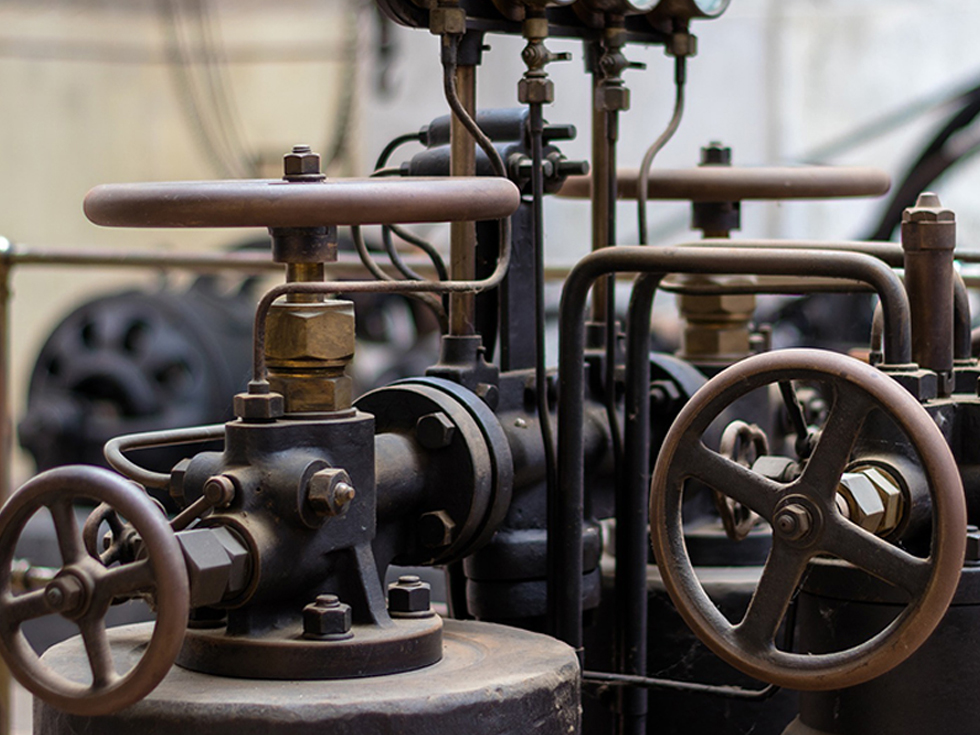

Blade gate shutoff Industrial Valves are a mechanical device used in commercial piping, utilized to open up. Regulate and also regulate the circulation of water via pipelines. There is some ask for the function of. With each other we will certainly review this in this short article. Industrial valves are utilized extensively in a lot of the most commonly made use of markets that any of us have actually ever before recognized: food production, drink manufacturing, pet feed production food & beverage, garment & dyeing, chemical production, water system, and also treatment, and so on

Depending on the atmosphere made use of, the installment location. As well as the demand to use the valve to pick the appropriate shutoff to open or change the price of the inside of the pipe. Currently, on the market, consisting of one of the most generally used valves such as: Round shutoff framework includes a round ball as well as an opening through the ball.