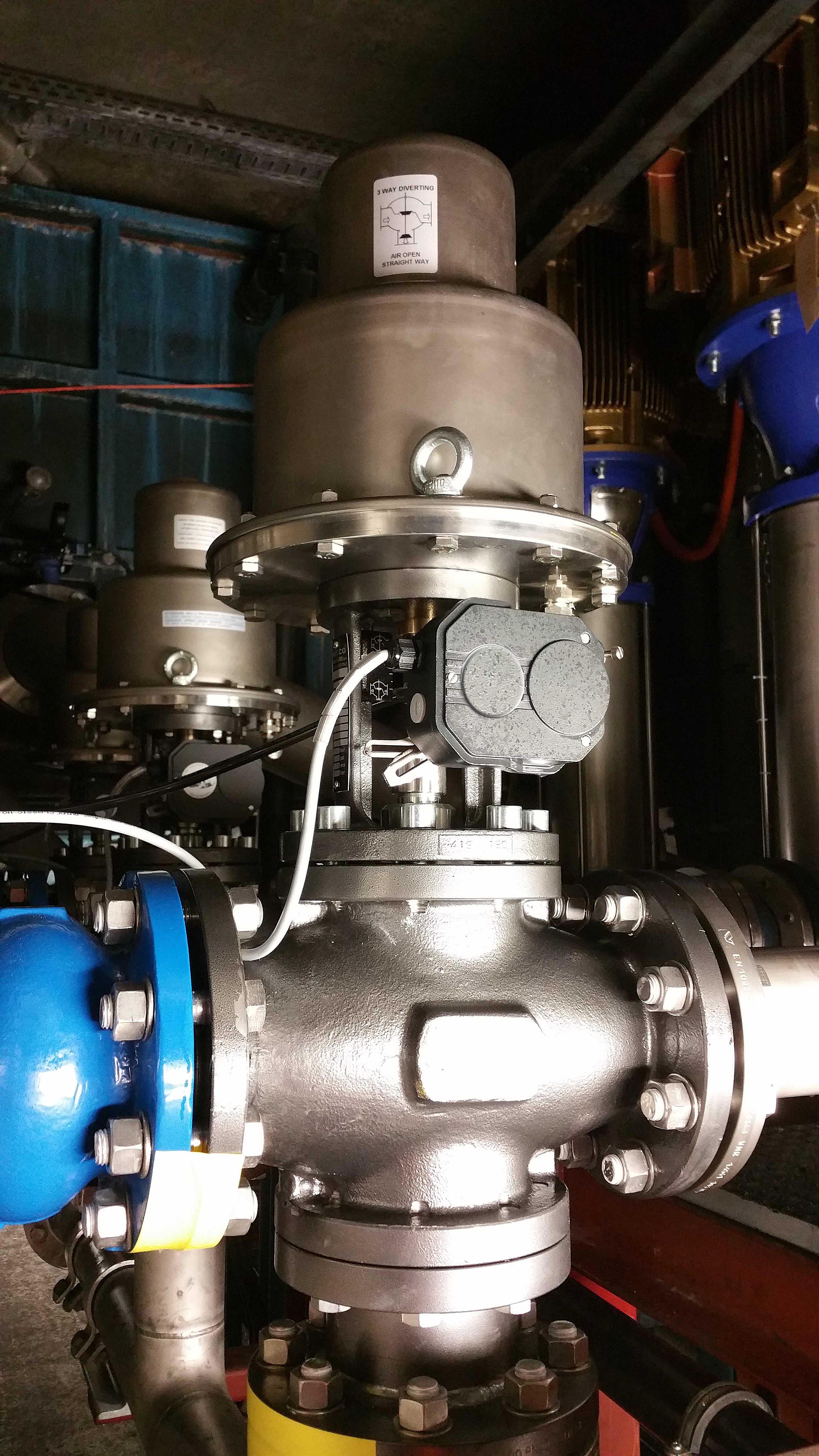

A hydrogen valve is a vital type of valve that is used for hydrogen storage at low pressures or high temperatures. Hydrogen is a widely used element in the chemical and gas industries as well as in alternative energy sector. Because of its benefits, many industries are able to use hydrogen inside their operations and machines. Many companies are already using this kind of valve in their production process.

These types of valves are used in processing lines, hydrogen tanks, and chemical plants. These types of valves offer many benefits. They make processing easier and perform better. They are also flexible, fast, safe, and reliable. Aside from these benefits, these valves also have the ability to protect the plant and machinery from possible contamination and failure. Below are the different types of hydrogen valves that are used in the gas and chemical industry.

We will first look at the most common high pressure ball valves used within the hydrogen service industry. As the name implies, high pressure ball valves are used for filling and draining water or other liquids. There are two types available on the market today: the ball-type which has a small hole and the screw-type which has a large hole. There are two types of ball valves on the market today. One has a small hole, and the other has a large hole. These valves are used in the manufacturing industry to inject chlorination water into the units.

Next, let us look at some of the common testing methods used in checking the performance of these valves. One of the most common testing methods is the dynamic pressure test. This method is usually performed in areas where there is a high leakage rate or large fluctuations. Other testing methods include thermal conductivity, tensile strength, and dynamic reaction, among others.

Hydrostatic strength and temperature range tests are another type of testing that can be used to verify the performance of these valves. The hydrostatic strength test measures the fluid's resistance to pressure changes due to expanding and contracting. The temperature range test determines the resistance of the valve to varying temperatures. The results of both of these tests can help in identifying the weak points of the system so that they can be improved before the installation.

The electrical isolation test is another type of testing. This involves inserting a 20-inch long copper wire into the hydrogen tank. This piece of wire is placed into the tank at room temperature and is exposed to the operation of the valves. If the wire gets too hot, it is a sign that the system is leaking. We can see that the valves work even at low temperatures.

Materials are also used to test the performance of valves. The composition of the materials used varies depending on the purpose of the valve. In addition to these materials, pressure testing and other techniques are also applied to evaluate the performance of the valves. This situation is common because water and graphite are used in pressure. The presence of hydrogen atom in the graphite results in the formation of hydrogen bubbles which are then observed as the pressure wave.

The infrared thermography is another type of testing that can be done on these valves. It looks for leakage of gas bubbles or black holes. Infrared thermography is a reliable method to determine the amount of gas leakage and black holes. This test is suitable for gases like hydrogen, oxygen, nitrogen and carbon dioxide. These gases have extremely high vapor pressures, so it is crucial to detect any leaks. Gas analysers are useful for infrared thermography.